The Hobby of Hobbies Strikes Again!

I can’t remember exactly when, but there was a point after I got my ticket when I started to see that all of these really cool kits for ham radio enthusiasts were practically buried in 3d printing. The last thing I needed was another pile of equipment, so I put that idea on the shelf and went about my business. Every once in a while, I would poke my head into the world of 3d printing and think, “Maybe? Should I?”

Something that I figured out quickly is that this particular pursuit had a very early dividing point. When one was selecting a printer, there was a decision: Do I want printing or the printer to be the hobby?

The earliest printers were pretty complex kits. The ones with the biggest names and followings could, at a certain point, be upgraded by printing the parts for the upgrade. In my heart, I love that thought. Being able to maintain a tool with parts created by the tool is the kind of thing that anyone who ever went deep on hard sci-fi would get into. But I don’t live on a starship at the outer reaches of the galaxy. I live in a world with time constraints. That, as always, narrowed the field.

Christopher M0YNG, the admin of Mastodon.Radio, responded to a general lazy-web style query I made to the hivemind at large and responded that if I wanted a printer that just did what I wanted it to do, the Anycubic Vyper was a good choice. I did a lot of shopping and poking around and came back to the Vyper. The price was right. It’s pretty user-serviceable. It works out of the box. All of these things were pretty great!

What Do You Do With It?

I have printed a lot of objects for my radio hobby with this printer. Sure, I did a test print of a rectangle with my callsign in it to make sure I could use the software. But I also looked up the plethora of models on the internet that related to my gear.

I made a face plate for the IC-705.

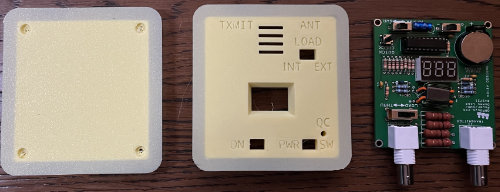

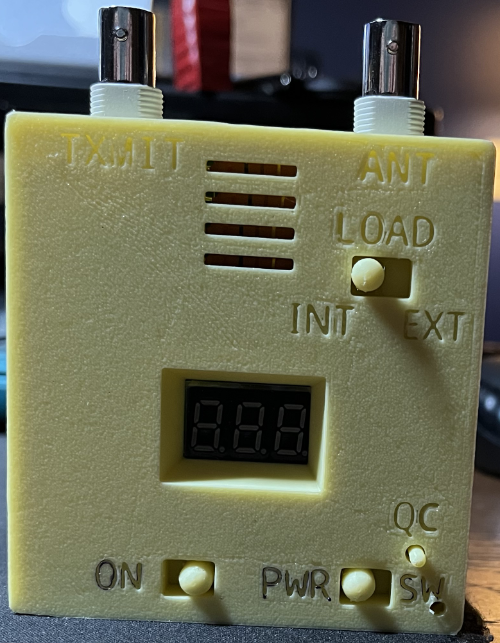

I printed a case – complete with switches – for my QRP Power Meter/SWR Meter/Dummy Load.

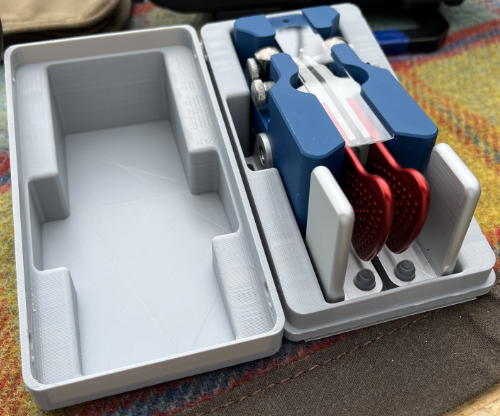

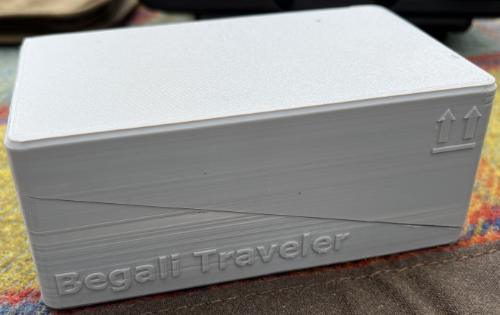

And I printed a box to keep my Begali Traveler safe when it’s bouncing around in my bag.

All of those are pretty neat! They didn’t take long and I didn’t have to do much to make sure that they came out in a useable state. Sure, my color choices are questionable, but that yellow filament was on sale.

The Best Part

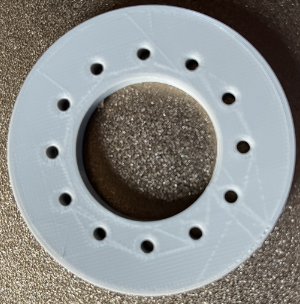

So many things that come with antennas or radios in general are little plastic widgets that could be described as a square of plastic with a specifically sized hole in it. Take for example the insulators that come along with EFHW antennas. Or even the rings that are used to attach guy lines to a mast. These are little bits that are easy to lose. Well, lucky for us (me) there are a lot of models out there already for replacing these bits and pieces. And honestly, printing one up costs less than shipping if, say, a dog has chewed up said guy line ring.

Being able to whip up one of those parts in under 30 minutes is pretty slick.

Other Uses

It’s not just ham radio where a dumb, plastic widget breaks or is lost and requires a ton of research to replace. There are bits of household appliances that have models on the internet. I’ve found a few of those and have proactively pulled down a model or two for the bits and bobs that are most likely to break.

As I get better with the modeling software, I am more confident that I can make things that are useful and not just cool owls and stuff.

Final

3d printing is a hobby in and of itself. I am not really in it for that, but I can see how one could easily go down that rabbit hole. For me, I see it as a low-grade substitute for the replicator on Star Trek. I’m not unhappy with what I’ve seen and done so far.

![]()